SKF Single-Line Automatic Lubrication Systems

SKF Single-Line Automatic Lubrication Systems, our new distributor as TPM Engineering, provide maximum efficiency by automating the lubrication process in industrial facilities.

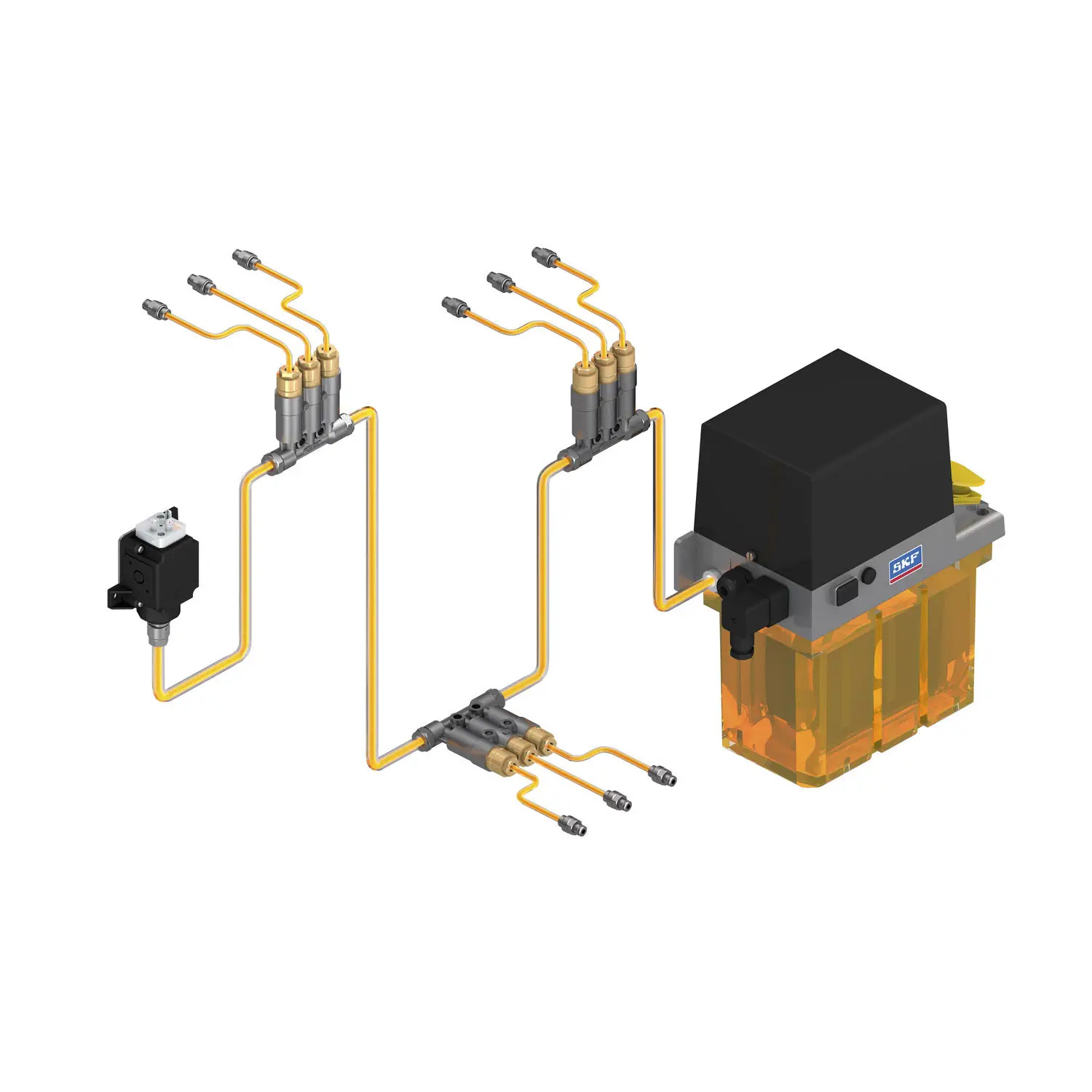

Regardless of the application, the operating principle of the SKF single-line lubrication system is the same:

A central lubrication pump station automatically delivers oil or grease to the distribution elements via a single supply line. Each distribution element serves a single lubrication point and can be precisely adjusted to the required amount of oil or grease.

These systems can be designed to:

lubricate a single machine,

different zones within a machine,

or multiple separate machines.

| Advantages: | Application Areas: | |

| · Easy to understand, install and maintain. | · Machine tools | |

| · Compatible with almost all lubricants (oil, fluid grease, solid grease, etc.). | · Printing machines · Road and off-road vehicles | |

| · Offers high reliability. | · Construction and forestry machinery | |

| · Easily expandable system structure. | · Cement industry | |

| · Even if a single lubrication point is blocked, the system continues to operate. | · Food and beverage industry · Railway applications | |

| · It can pump long distances and operate in a wide temperature range. | · Iron and steel industry, etc. · Automation systems |

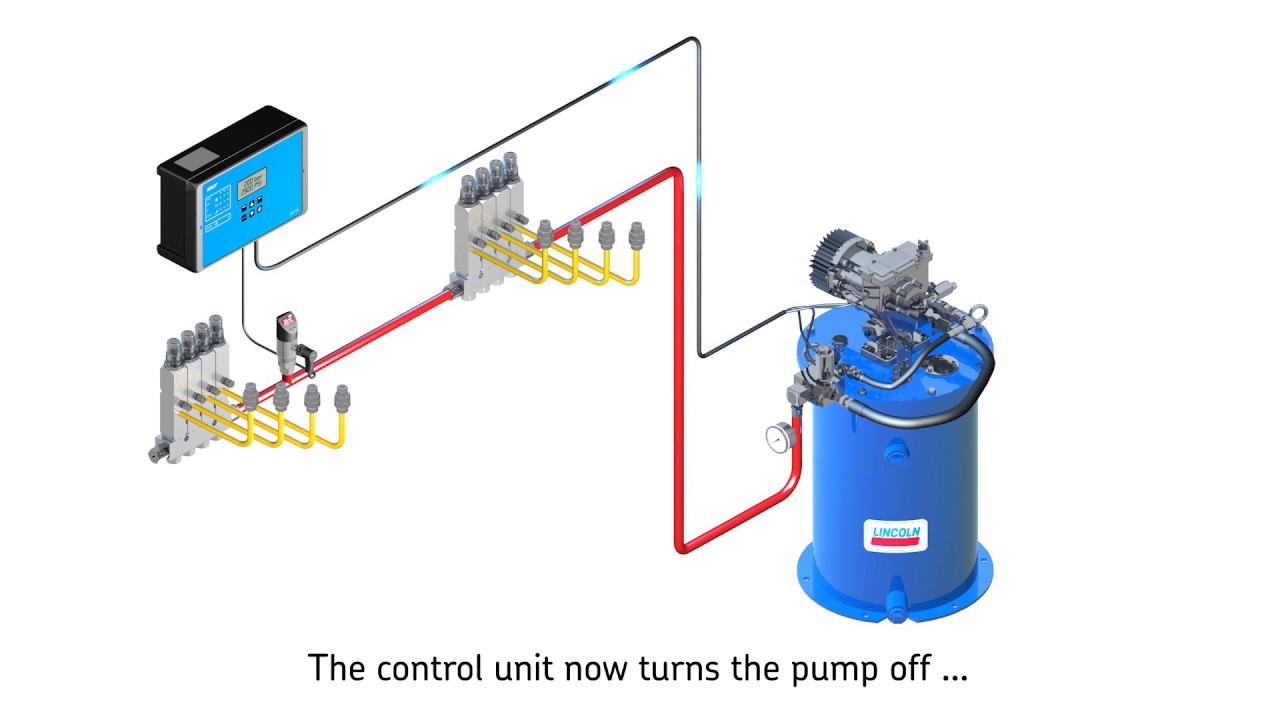

How Do SKF Single-Line Lubrication Systems Work?

All single-line distribution elements operate almost in parallel. Two different operating principles can be applied:

1. Pre-lubrication distribution elements:

The pump delivers the lubricant to the distribution elements via the main line. These elements transfer a fixed amount of lubricant stored in advance to the lubrication points under the influence of the pump pressure. Then, the pressure in the main line is reduced, and the reservoir inside the distribution element is prepared to be refilled. In the next lubrication cycle, the lubricant is transmitted again.

2. Re-lubrication distribution elements:

During the lubrication cycle, the lubricant fills the storage chambers of the distribution elements. However, this lubricant is delivered to the lubrication points after the main line pressure is released (this effect is called “re-lubrication”).

In both types of distribution elements, the dosage amount can be easily adjusted by changing the dosage nipples on them.